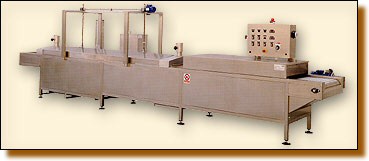

REFRIGERATOR CABINET

Refrigerated and ventilated cabinets.

Inner and outer stainless steel

AISI 304 (galvanized back part). thermometer

Programmable digital. Interior lighting.

Refrigerant R 134 A of the ecological type (for BT R 404 A). Versions available with whole doors, half doors, glass doors.

Triple seal on the doors/